Why Choose Fibre Cement

Fibre Reinforced Cement (FRC), or simply fibre cement, is a popular building material developed by James Hardie in the early 1980s, when pioneering the use of alternative reinforcing materials to create asbestos-free cement-based building products.

Why choose Fibre Reinforced Cement?

Fibre Cement building products by James Hardie will not burn, are resistant to permanent water and termite damage, and, when installed as directed, are resistant to rotting and warping to the extent set out in James Hardie’s published material current at the time of installation.

The products are easy to work with and low maintenance, making them the ideal choice for professional builders, designers and architects, DIY enthusiasts and homeowners.

Smarter building for better living.

Beautiful Endless versatility so you can create your unique dream home. | Enduring Built for tough Australian conditions. | Space maximising Live larger and make the most of space. |  Easy Faster and simpler construction through reduced onsite trades. |

Building your vision.

Traditional charm. Bold modern lines. Or a mix of both? Whatever your vision, fibre cement products by James Hardie offers the ultimate design flexibility so you can create a lasting dream home that’s as individual as you are.

Love where you live, longer.

Lasting protection with fibre cement products by James Hardie. Fire resistant, impact resistant and resistant to damage from moisture and termites. Built for tough Australian life - it is low maintenance, ready for what life throws at it.

Adapts to life, creating the spaces you need.

Live larger with fibre cement products by James Hardie. With advanced thermal qualities for temperature control and lightweight construction to maximise floor space - you can live more comfortably too.

Loved by the trade for better building.

Homes are built for living. And fibre cement products by James Hardie is made for faster, easier building. Trusted by builders, it’s lightweight and easy to work. So construction time can be quicker and you can start living sooner.

What is Fibre Cement made of?

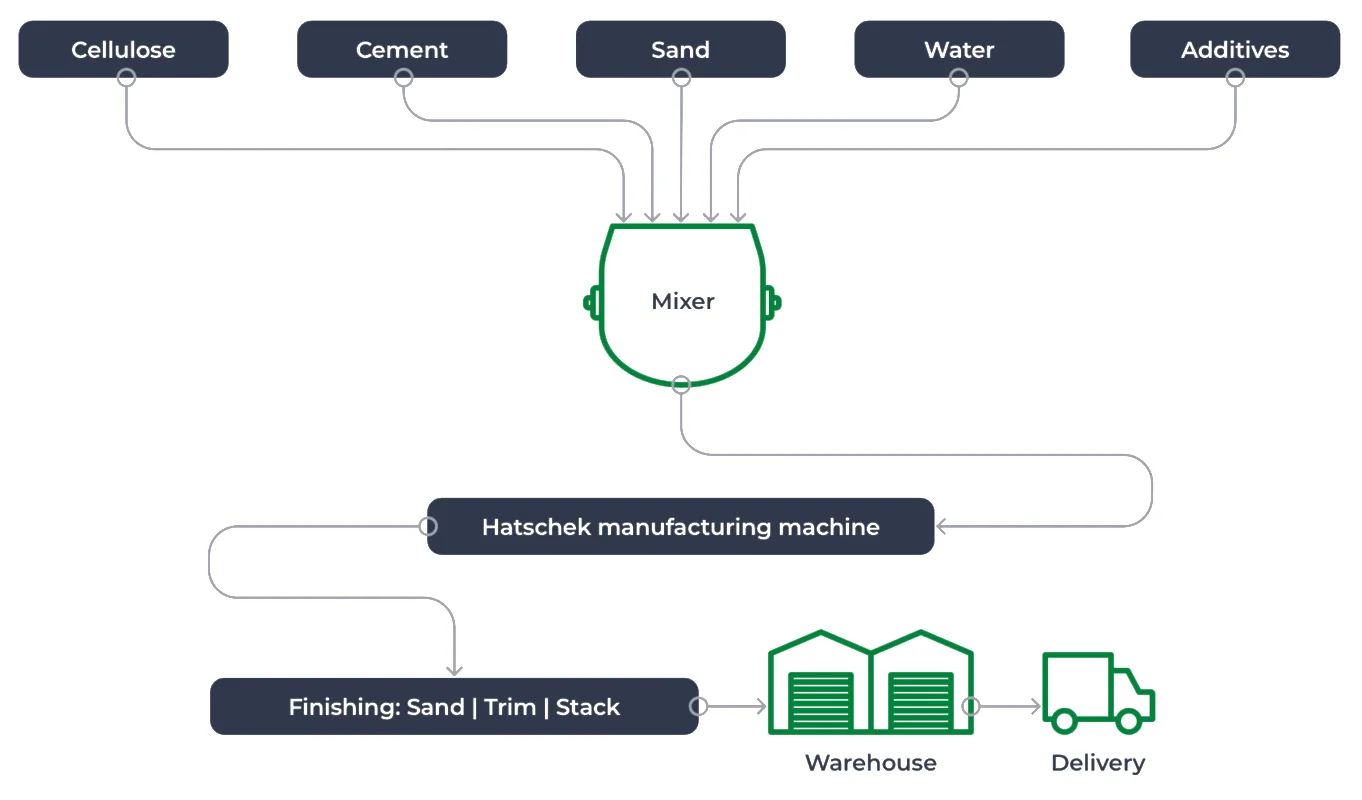

We use a mixture of cement, sand, water and cellulose fibre, sourced from sustainably-grown Pine trees.

Small amounts of other chemical additives are used to help the process, or provide products with particular characteristics. This means that Fibre cement has our trusted level of durability, fire, impact and moisture resistance, and aren’t succeptible to rot or termites like conventional fibre panels.

How is Fibre Cement made?

The fibre cement manufacturing process produces a durable, highly workable and aesthetically pleasing product by a process that substantially reduces the curing time compared to air-cured concrete products. This means your build moves along faster, with less hold ups and complications.

You can always rely on the quality of a James Hardie® building product as all our Australian manufactured fibre cement products meet ISO 9000.1 quality assurance standards. This also ensures James Hardie operates with:

- Increased quality awareness

- Improved and earlier awareness of potential problems

- Improved customer service

- Improved management of quality

- Improved product and service quality

What Fibre Cement products do James Hardie make?

James Hardie manufactures the largest, most versatile range of fibre cement products in Australia. They are all used extensively in the construction of new homes, in renovations and restorations and in commercial buildings for:

External cladding

Internal lining

Wall Systems

Flooring

The products are diverse, coming in numerous profiles and finishes for a range of interior and exterior building applications that suit most architectural styles.